Modular installations are an innovative way of assembling installations in a building using modern technology.

With the advancement of computer technology in recent years, there is now a tremendous opportunity for the commercial construction industry to change through the off-site prefabrication of MEP components which can then be assembled on site.

MEP modules not only facilitate coordination but also introduce manufacturing efficiencies to the traditionally complex mechanical and electrical industry.

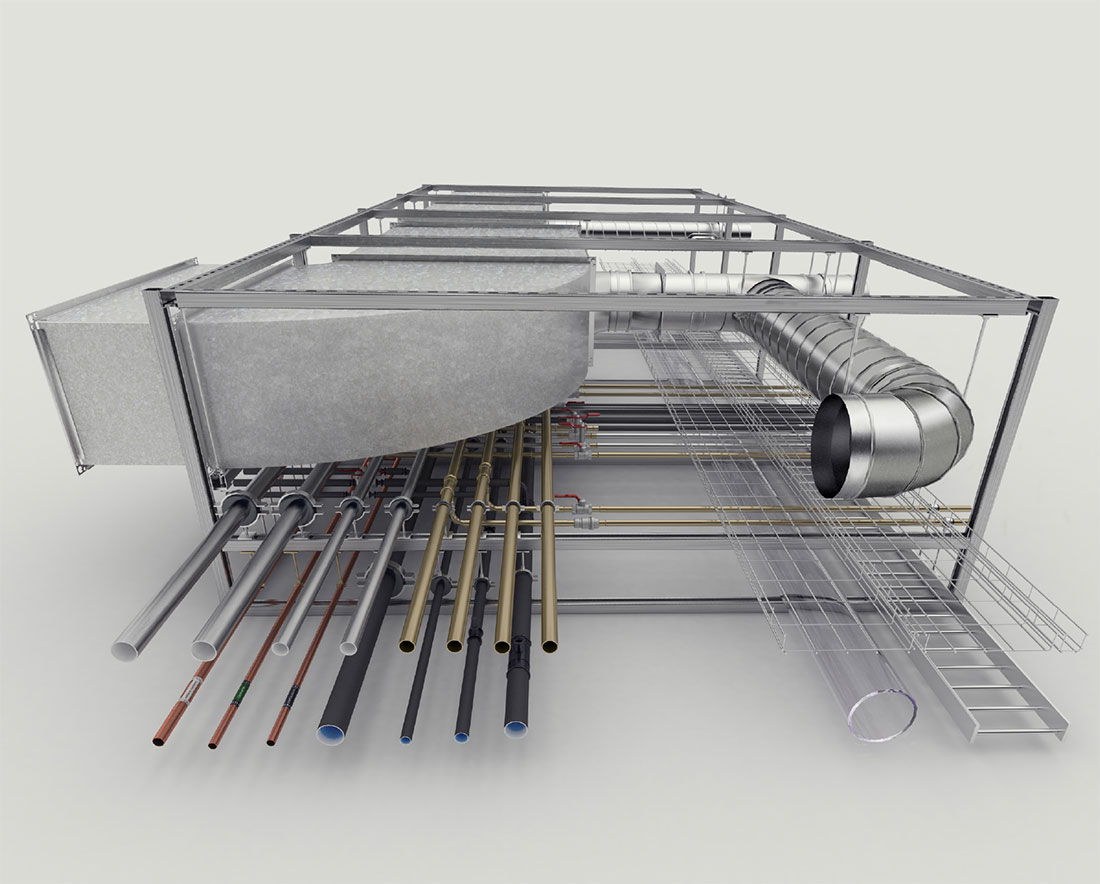

A typical MEP module consists of steel frames to which cable trays, pipes and ventilation ducts are attached. These modules can be anything from 6 to 12 metres long, but width and height are limited by the fact that they then have to be transported to the construction site.

The design of MEP installation modules is similar to the preparation of a coordination drawing, but also involves a rethink of how the modules are connected including a calculation of the size and weight of steel beams used to make the mounting frame.

MEP modules can be fabricated in two ways: in a workshop outside of the construction site or on the construction site in a temporary workshop where they can be easily transported to the place of installation.

Installation of modules tends to be carried out by chain block or duct lifters. A tower crane is also sometimes used to assemble modules in shafts.

Advantages of prefabricated MEP installations

- Quicker completion time – instead of waiting for a team to open an area and issue MEP clearance, the work can start much earlier off-site.

- Lower execution costs – which may surprise you. Many contractors think that the cost of prefabricated MEP systems will be higher, but it isn’t necessarily. The initial expense may be higher due to additional coordination costs, a greater use of steel, and the purchase or hire of appropriate lifting equipment, but the time of completion will be quicker, and the workload will be significantly lower, meaning you will get a return on your investment much quicker.

- No damage to other services by trades. MEP modules are installed from the ground floor meaning you can avoid any damage to other services. Carrying out work in a dedicated workshop is much easier than doing the same thing from scaffolding.

- Improved health and safety due to less work on scaffolding.

- MEP installations tend to be of a higher quality thanks to the use of common supports for all services which improve the clarity of installation

- Easier workforce planning as modules can be made however ready (or not) construction works are.

Disadvantages of prefabricated MEP installations

- Modules will not apply for large dispersed installations, such as garages or single-family houses as they are only worth installing in the corridors of commercial buildings or lobbies.

- Drainage pipework often cannot be installed modularly because of the slope involved.

- Resistance to new ideas and the need for additional drawings discourage many engineers from getting involved in prefabricated methods of installing MEP services.

Installation methods of MEP services have a huge impact on the time and cost of construction projects, and modular installations can not only shorten the lead times but also improve the level of safety on-site and the quality of installation.

It is definitely worth using modular installations of MEP in commercial buildings such as hotels, offices and shopping centres, and also multi-residential buildings as well. The CAD Room has lots of experience in providing MEP modelling and prefabrication services for architects, general contractors, MEP engineers and structural engineers – so please don’t hesitate to contact us to find out more.