DfMA (or Design for Manufacturing and Assembly) is a new approach that is being undertaken in the construction industry aimed at promoting the use of off-site fabrication of many materials used in the construction process.

Allowing for a substantial amount of work to be completed in a controlled manufacturing environment means not only is manpower and time to construct buildings reduced but worksites also stay safe and there should be minimal impact on the environment as well.

Prefabrication in construction is not a new idea, modular buildings have been around since 1945 for example. But technology has come on in leaps and bounds since then, which has led to the promotion of DfMA as a way of improving the productivity levels of this typically manpower-intensive industry.

What is PPVC?

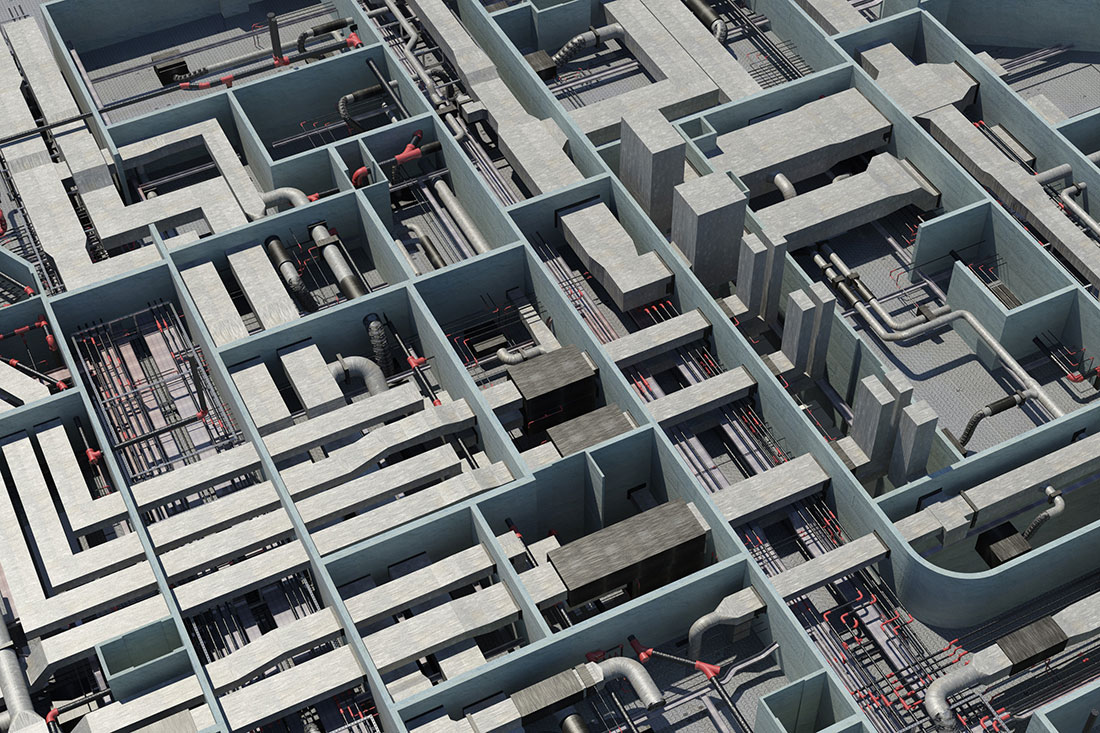

One of the so-called ‘game-changing’ technologies that have brought this new focus is PPVC – also known as Prefabricated Prefinished Volumetric Construction. This process means that complete modules of multiple units completed with internal finishes, fixtures and fittings can now be manufactured in factories, and then transported to the end site where they are put together – a bit like Lego pieces.

In traditional construction, most of the trade works involving architectural, MEP, and structural elements are both constructed and installed on-site – making them very manpower-intensive processes. With PPVC, free-standing modules (complete with finishes for ceilings, walls and floors) are manufactured and assembled in an accredited facility and then installed in a building under building works.

What are the benefits of PPVC?

There are many benefits associated with PPVC, including:

- Better Construction Environment – As more of the building activities are being completed off-site, there will be less dust and noise pollution on-site, and less on-site construction waste

- Better Quality Control – The final product will be delivered from a controlled factory environment, leading to increased reliability due to the higher quality of finish. The sequence of work can also be planned more effectively, with better logistics coordination as well

- Improvement in Productivity – Lots of different parts of the build can be worked on in the factory at the same time, which will streamline the whole building process as well as significantly reducing the on-site construction time

- Reduction in On-Site Manpower – The more construction that can take place off-site, the less time needs to be spent on site which will also lead to better working conditions and the enhancement of worksite safety

BIM and DfMA need to work hand in hand for the construction industry to move forward and really develop itself with the times – and deliver on the Government Construction 2025 report. Working with The CAD Room as your BIM outsourced service partner can really help you to do that. To find out how contact us today on 0161 427 0348 or email us at office@thecadroom.com