We recently added Surveying to the range of quality services we already offer here at The CAD Room. These services are based on the use of 3D laser scanning in order to ensure we can cover large areas accurately and efficiently.

In this post, we are going to take a closer look at the techniques and processes used in 3D scanning.

History of 3D Laser Scanning

3D Laser Scanning is not a new technology, although it may sound like one. It was introduced back in 1960 – although the machines used were nowhere near as portable as they are today!

In fact, it is only in the last 20 years that the technology has developed enough for us to be able to use and store large data files effectively. Laser scanning technology has also become more cost-effective to manufacture, which has also made it a more commercially viable option for design and project management.

What is 3D Laser Scanning?

The 3D Laser Scanning process relies upon the scanner transmitting a laser beam until it hits an object. At this point, the light is reflected back and captured by the scanner. The light will return to the scanner at a slightly different wavelength than when it was sent, and it is this variation that is measured.

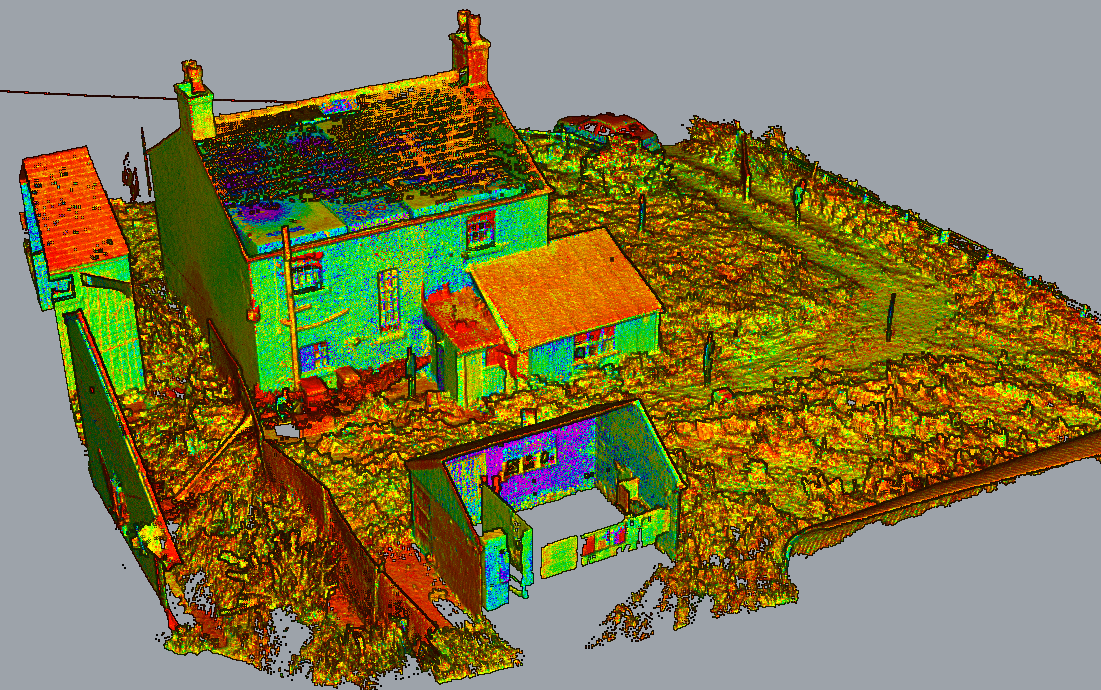

As light travels at a constant speed, the variation in wavelength can be calculated as a distance. 3D laser scanners can repeat this process up to a million times a second to create a 3D image consisting of millions of dots – usually referred to as a point cloud.

What are the benefits of a 3D Laser Survey?

A 3D Laser Survey offers construction companies a safe and fast solution to the issue of obtaining accurate, on-site measurement data. It is also ideal for design and project management applications as it is supported by three-dimensional imagery.

What different types of 3D surveys are available?

There are various different types of 3D Laser Surveys available, and the best one for you will depend on how you want to use the information, and the final outcome you would like. Whichever type of survey you lean toward, however, you will receive a digital 3D model at the end. Remove this as we often use the scanner to deliver 2D plans and elevation or even just the point cloud itself

What is the registration process of a Laser Survey?

Once the Laser Survey is complete the individual scan data needs to be processed, aligned and fitted together. Most modern scanners are capable of completing this as they are scanning, but it is always wise for the surveyor to check to ensure alignments and tolerances have been taken into consideration.

As more and more scan points are joined together a 3D image made up of millions of points is created, and this is called a point cloud. When individual scans are processed together, the registration software will look for the best fit between each scan point that overlaps. Once all scans have been registered, the combined deviation is totalled up in order to provide an overall survey accuracy.

One way we can improve on the accuracy of scan results is to set out spheres or targets on-site, in order to assist with the registration of scans. This is dependent on the size and duration of the project targets of course.

3D laser scanners have built-in compasses, dial access compensators, GPS, inclinometers and sensors to aid with alignment – but these are often limited as they tend to use similar technology to smartphone apps. The use of spheres allows exact GPS coordinates to be allocated to that position, meaning the rest of the point cloud can be aligned as well. This is particularly useful for topographical surveys as it means the scan data can be aligned with the sites datum and elevation which can then be noted on all relevant documentation.

What can we do with 3D scan data?

Once we have captured the data, we will present it in whichever format the client prefers. We will first store the final point cloud, which will be digitally compatible with most major software applications such as AutoCAD, Revit and Solidworks. We can then produce a 3D CAD Model or a 2D printed version for any fabrication drawings or plans.

Another service we offer is the utilisation of the point cloud. Although you may already have an accurate 3D representation, this can be overlaid with the point cloud to help with clash detection without the need to model the entire site.

3D scan data can also be fed into your BIM model which will contain all documented details and information about the building structure and services. This will then become a digital blueprint that allows all parties involved in the initial design, construction, occupation and management of a building to be able to easily and accurately identify all of the individual items that have gone into the makeup of the building.

If you would like to know more about 3D laser scanning, or any of the services we offer that can help you transform your design into the 3D world, then please do not hesitate to contact us. We are more than happy to help.